ELECTRICAL THERMAL IMAGING INSPECTION

Inspect beyond and protect your production

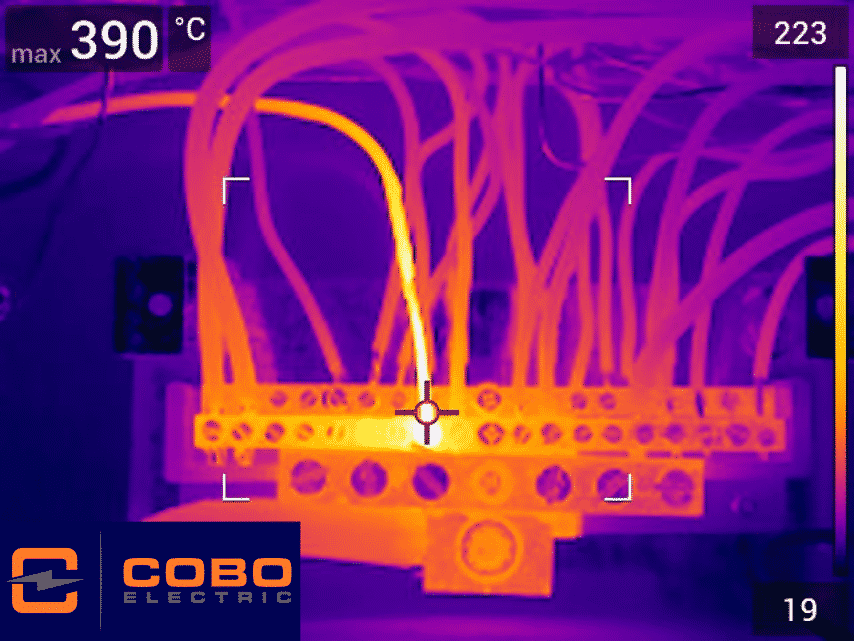

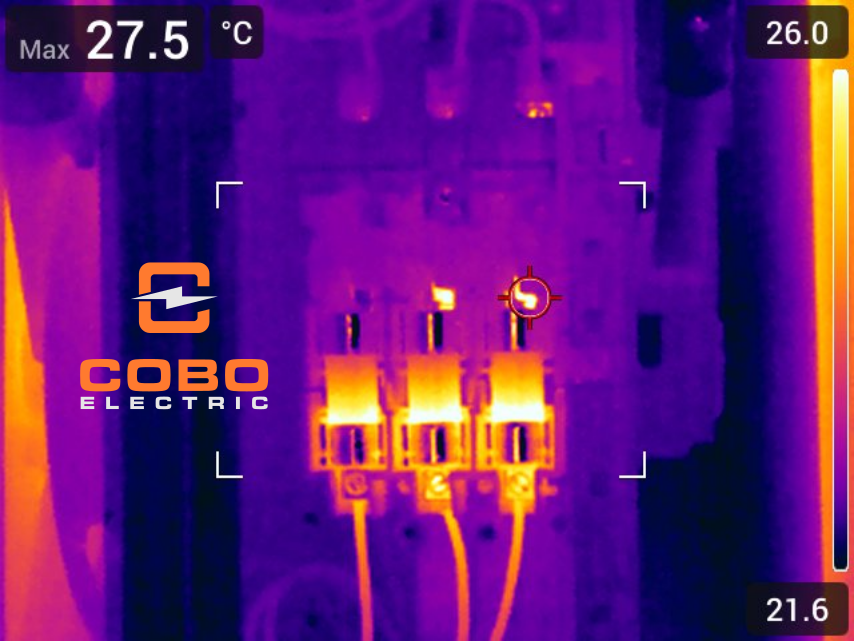

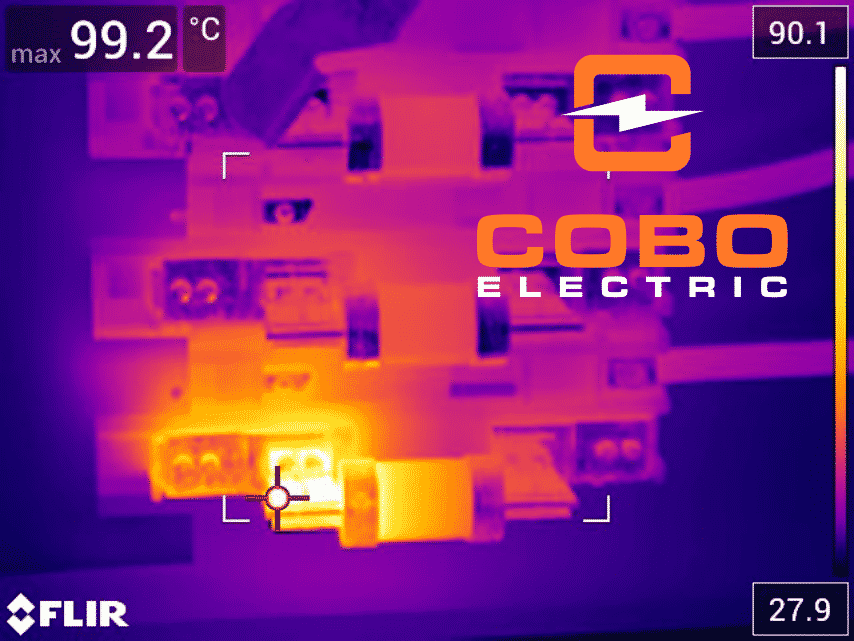

To begin with, we do Industrial electrical thermal imaging and commercial electrical thermal imaging inspections. In order to detect potential fire hazards. Certainly, to ensure your electrical is running at its safest.

Electrical Thermal Imaging

We have a team of highly skilled and specialized techs. Hence, we are electrical experts ready to take on the most complex projects.

Electrical Thermal Imaging Inspection Detections

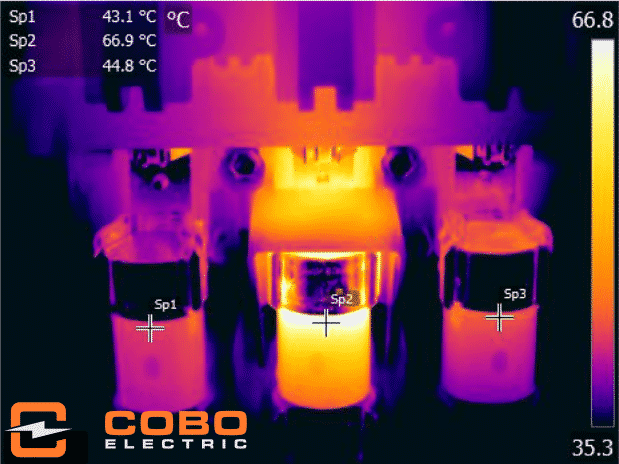

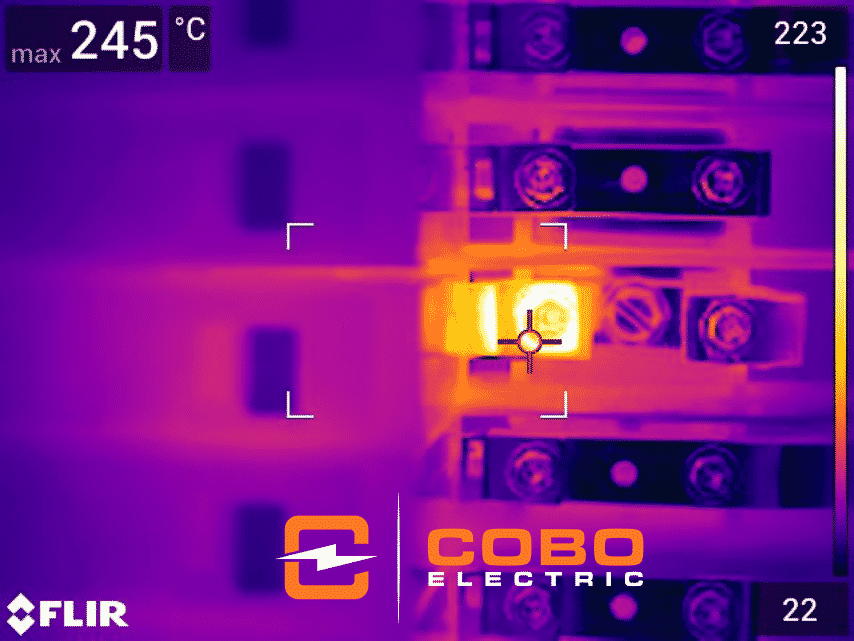

Firstly, the flow of current along an electric system generates heats. To point out, other electrical units and parts spawn heat depending on their state. That is, when any part of the electric system is strained, it heats up a lot. To that end, it is such odd heating that we, through the help of thermal imaging, would be looking for. To repeat, a heating element along the electric system is a clear sign of a fault. Nevertheless, below are conditions that generate heat in an electric circuit.

Old Wiring

In general, aluminum wiring poses a fire threat with a higher rate of expansion and contraction. In the event that can lead to loose connections. Also, Knob-and-tube wiring is a thing of the past. In particular, insurance companies require it be replaced.

Deteriorated Connections

In like fashion, old electric wiring can fall apart and pose a safety hazard for many reasons. Hence without your knowledge. In time, insulation protecting the inner wires of your electrical system can break down due to aging. Sooner or later could cause electrical shorts. To be sure, get a thermal imaging electric inspection.

Loose Connections

Albeit, wires are under a constant cycle of heating and cooling. Coupled with expansion and contraction. While every time a motor is used or appliances are plugged in, the natural result of all this usage is that wire connections can loosen over time. Likewise, loose connections can occur in poor installs.

Overloaded Circuit

It must be remembered that electrical wiring and breakers in your industrial facility are designed to handle a specific amount of electricity. On account of adding devices, appliances, outlets and other controls. Sooner or later, it increases the load on the circuit. That is, passing the rated load causes heat in the wiring and at the terminals. Thus risking a potential fire hazard.

Reduce risks

Our electricians perform electrical thermal imaging surveys on your equipment. Ultimately, to see potential fire hazards and ensure your electrical is running at its safest. Our techs are licensed and certified using non-contact thermal imaging cameras. This can be performed at any time of the day. Of course, without having to shut down the in-use equipment or electrical supply to your building.

Loss Prevention

Insurance brokers favour to put into effect electrical thermal imaging reports into their loss prevention plans. In truth, getting a regular thermal scan is considered a preventative maintenance measure. And it can reduce your insurance cost. On the positive side, also lower equipment failure costs.

Field Review

Our techs will do an on-site inspection of all the equipment in question. At first, we test for overloaded circuits and faulty wiring. Additionally, loose connections, construction defects, post-fire damage and others.

Reporting

After every analysis, a detailed report is generated. Thus, stating the equipment surveyed and findings. Wheres we give our recommendations for repairs and maintenance.

Repair

We are certified Red Seal electricians. And, we can perform the necessary repairs to get the problem areas fixed immediately.

Interested in an electrical thermal imaging inspection? Send us your information and we’ll get back to you ASAP.

Electrical thermal imaging contractor

Electrician for Infrared Inspections

How much does an infrared electrical inspection cost

Electrical Thermal Inspection

Transformer Inspection with thermal imaging

Electrical Contractors Winnipeg for Electrical Thermal Imaging Inspections

Infrared Thermography Inspection

Electrical Thermal Imaging Winnipeg

Thermographic Scan Electrical